Material of the Month

Can you guess what this is?

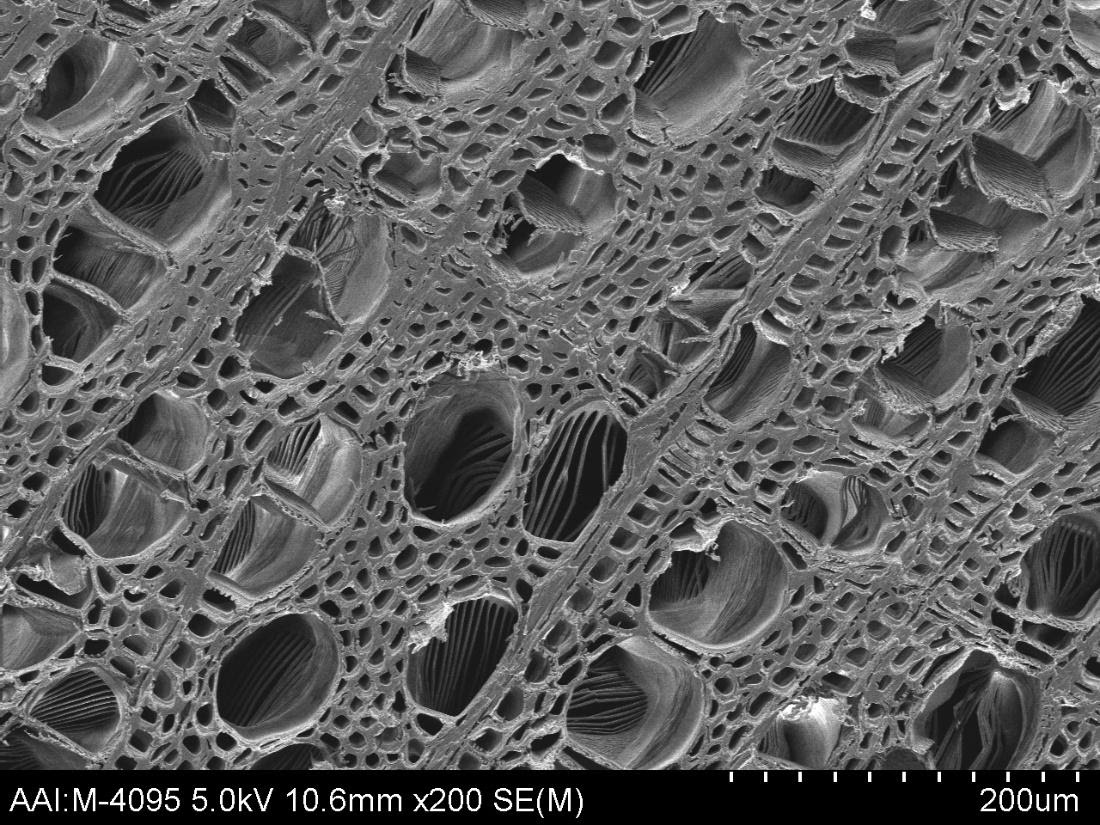

High surface area materials are important in many areas of industry and research. Catalysts, fuel storage, chemical separations, and novel battery applications all benefit from having a high surface area. The high surface area allows for more active sites per volume, allowing for greater efficiency in systems like catalytic converters. Nature has generated many types of high surface area or microporous materials, such as zeolites, which are found naturally and are also produced synthetically for industrial use.

While an important characterization method for microporous materials is to measure the surface area, this method does not show the structures involved. Examining the structure visually is beneficial to understanding why they work, or when they don’t. A beautiful cross section like the one above can be difficult to achieve with normal means, like microtome or mechanical polishing. The above section was created using ion beam polishing in the Broad Ion Beam system here at Analytical Answers. This non-contact method of sectioning produces near-distortion free sections ideal for examining small structures in the scanning electron microscope. In addition to structures like these, it excels at damage-free sectioning of semiconductor samples, platings, and optical coatings.

The Broad Ion Beam prepared microporous sample shown above is another of nature’s creations: wood!