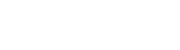

Real-Time High Resolution X-Ray Microscopy (XM)

(Failed conductor in a household appliance.)

What Is It?

Through high-resolution X-ray microscopy, we are able to non-destructively examine the internal structure of samples in real-time,at magnifications up to 1000X.While the internal mechanisms of these samples are usually not visible under other means, XM offers us a tool to watch them in operation.

Why Should I Use It?

Unlike static radiography systems, XM allows the sample under examination to

be positioned in a direction that permits the best view of a feature of interest. The sample is able to be move in the X, Y and Z directions and can also be tilted and rotated. When images are calibrated, radiopacity (ASTM F640) and linear measurements can be made.

What Do I Get Out of It?

Video recordings of switches, relays, and other mechanical or electromechanical devices can be made to understand their inner workings or perform failure analysis.

Applications Include:

- Dispersion of fillers polymers

- Delamination in thin films

- Real-time evaluation of electrical and thermal devices

- Real-time evaluation of micro-surgical implements

- Opens/shorts in bond wires

- Bond wire placement

- Loose or Extraneous components in packages

- Construction details

- Deformed internal components

- Micro-fracture detection in materials

- Ball Grid Array (BGA) voiding in solder balls

- Voids or cracks in welds

- Die attach voiding

- Linear measurements

- Inspection of medical products while in sterile packaging

- Clearance between embedded wires